Explore The Possibilities of Laminate Countertops at S&W Cabinets

Today’s Laminate Countertops …

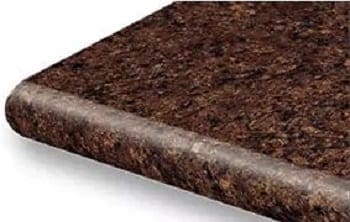

- Mimic natural stone perfectly

- Cost half the price of granite

- Won’t hurt your resale value

- Are highly heat resistant

- Are nearly impossible to stain

- Are more impact resistant than stone

- Are usually antimicrobial

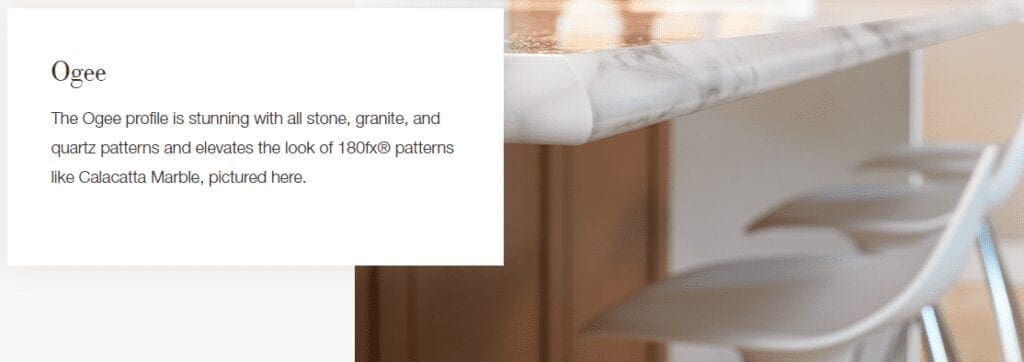

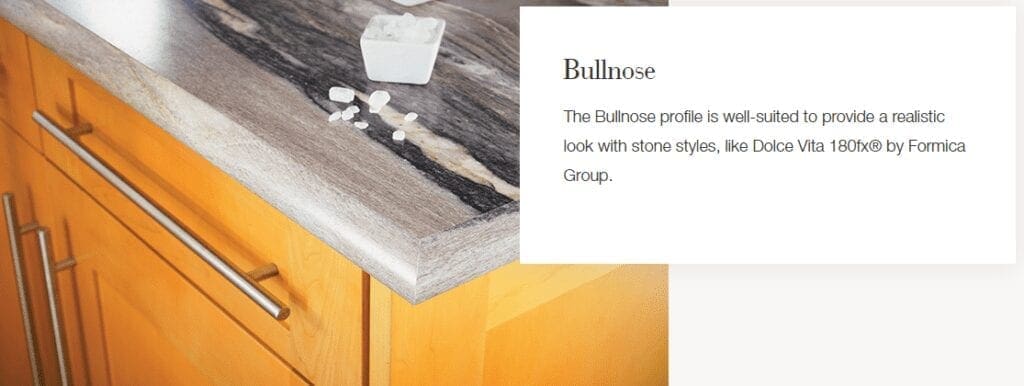

- Can be bullnose or ogee

- Can use with an undermount sink

- Are easier to maintain than stone

Choosing your colors and hoping they coordinate can be a bit overwhelming. Fortunately, Formica® & Wilsonart® have simplified this and made it fun for you

Just click on one of the buttons below and it will take you to the Formica® Design-A-Room or the Wilsonart® Interior Designer Tool where you can choose from a vast array of colors for countertops, backsplashes, walls, and flooring. Easily change the colors of everything in the kitchen to see what looks good together, and what doesn’t

Once you’re happy with your selections, simply print it out and bring it in to us. We’ll take it from there.

Be sure to stop by our showroom too. We love helping people plan their projects and we have lots and lots of samples for you to look at and/or take home with you.

Formica® Laminates

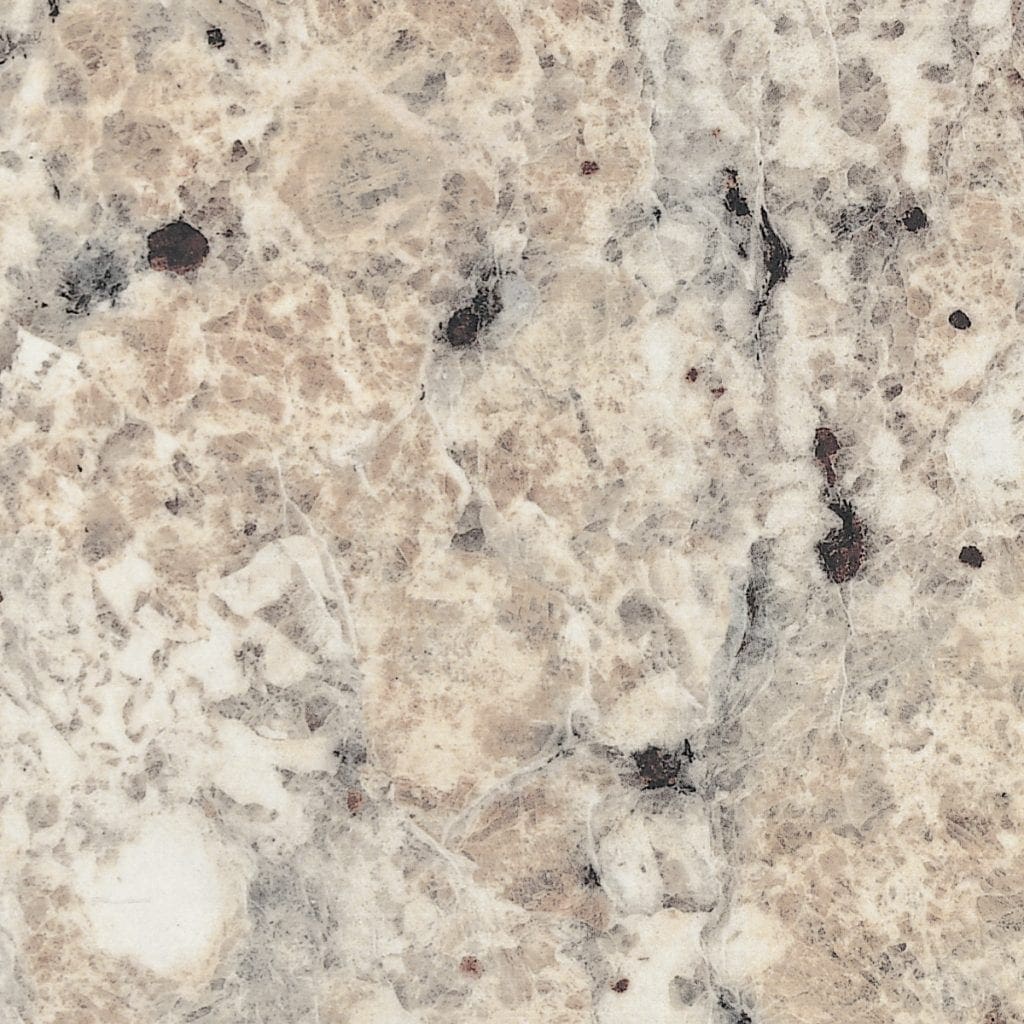

Here are a few of the stock color options available from Formica®

CLICK ON A SAMPLE BELOW TO VIEW A LARGER IMAGE

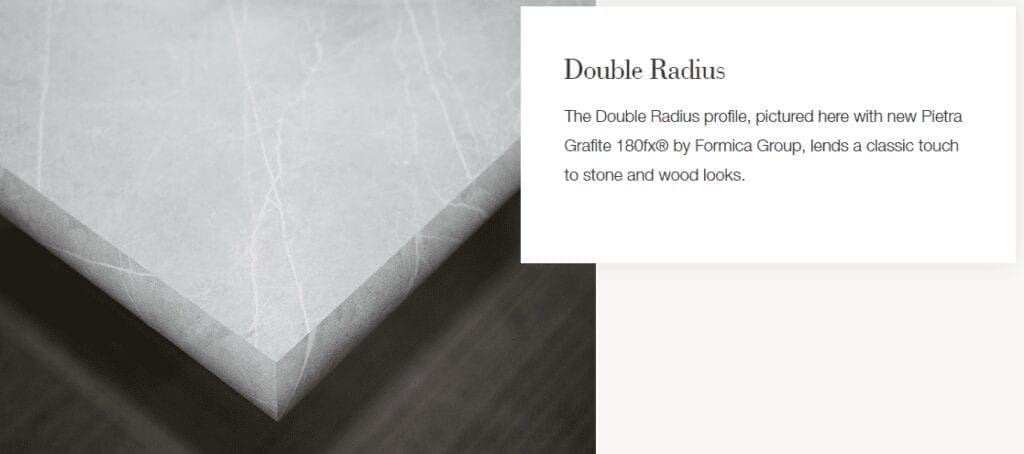

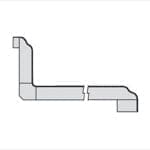

Countertop Edges

IdealEdge® Profile

IdealEdge® profiles are available in almost all Formica® Laminate and 180fx® by Formica Group patterns. Ordering is easy: Just choose your desired pattern and profile of IdealEdge® Decorative Edging when you are ready to order your countertops, and we’ll take it from there.

Pionite Laminates

The Pionite brand of laminates leans toward traditional tastes while offering versatility. With a broad range of tasteful and timeless designs, combined with long lasting durability, Pionite brand laminates are designed to enhance a wide range of surface areas.

Whether it’s residential or commercial, architects and designers specify Pionite® HPL for:

- Countertops

- Vanities

- Cabinets

- Store Fixtures

- Furniture

- Post-forming

- and much more.

Here’s a sample of colors that are available

CLICK ON A SAMPLE BELOW TO VIEW A LARGER IMAGE

Nevamar Laminates

For over 80 years, Nevamar has been known for its upscale, stylish and innovative designs, making it a favorite among the A&D community. Featuring a dynamic range of trend-setting styles, our design aesthetics are perfect for customers looking to achieve a more sophisticated vision.

Our proprietary Armored Protection (ARP®) delivers impeccable performance, surpassing rival laminates, while keeping patterns looking new for years to come.

NEVAMAR® HPL is the surface solution of choice for high-use applications on surfaces in:

- Hospitals

- Stores

- Hotels

- Offices

- Lobbies

- Restaurants

- Educational

- Institutions

CLICK ON A SAMPLE BELOW TO VIEW A LARGER IMAGE

Arborite Laminates

CLICK ON A SAMPLE BELOW TO VIEW A LARGER IMAGE

Countertop Edges

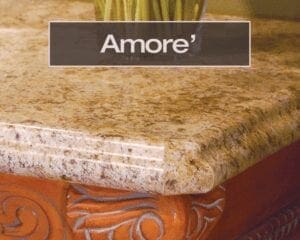

Amore’

Make any room in your home a work of art with the Amore’® sculptured series laminate countertop. Hartson-Kennedy’s Amore’® profile is unique in its’ subtle, refined curves. This beautiful profile gives a classic edge to your kitchen or bath that emulates the luxurious look of stone. Combining the Amore’® profile with the patented Amore’® Profile End Capping Process results in a laminate countertop that is unsurpassed in style and beauty. This edge profile is not available in plywood.

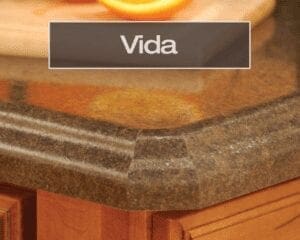

Vida

The Vida® profile offers yet another sculpted style from Hartson-Kennedy. The unique, subtle curves add a classic look to this profile which finishes in a uncurving bottom edge. This effect gives the Vida® profile a more substantial appearance, further emulating the look of stone. Our quality postformed laminate countertops are a cost effective way to add beauty to your living and work environments.

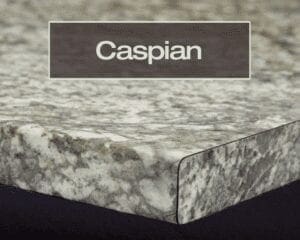

Caspian

Our stylish Caspian gives you a contemporary look with a double tight-radius profile. This edge compliments both classic and contemporary kitchen and bath design trends. This edge profile is not available in plywood.

Aegean

The Aegean gives you a sleek, eased edge without the black line common to many laminate countertops. This clean edge beautifully complements both residential and commercial applications. This edge profile is not available in plywood.

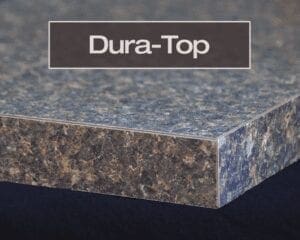

Dura-Top

A contemporary design featuring self-edge front and cove self-edge backsplash. This refreshing style blends beautifully with today’s modern appliances. Its dazzling design will enhance the beauty of any kitchen or bathroom giving it that ultimate look.

E-Top 1500

Crisp European styling with today’s new trends in mind. E-Top 1500 has a 180° front nose, 1-1/2” thick. The laminate wraps around the front nose giving added protection. This sleek, gorgeous design will enhance any room.

E-Top 2000

The 90°/90° oval, flat-front roll nose complements today’s cabinets creating a luxurious look. The laminate wraps around the front nose giving added protection. More curves, softer flowing lines, just the right touches.

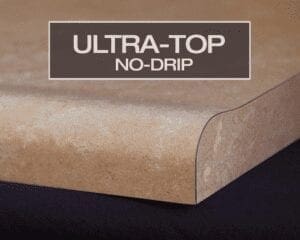

Ultra-Top No-Drip

Ultra-Top No-Drip has been the top choice in the industry for over 40 years. This one has all the features built right in. A raised rolled edge on the front nose meets the needs of today’s fast paced lifestyle. Beautiful and functional… it stops those messy spills from running down your cabinets and still looks fantastic!

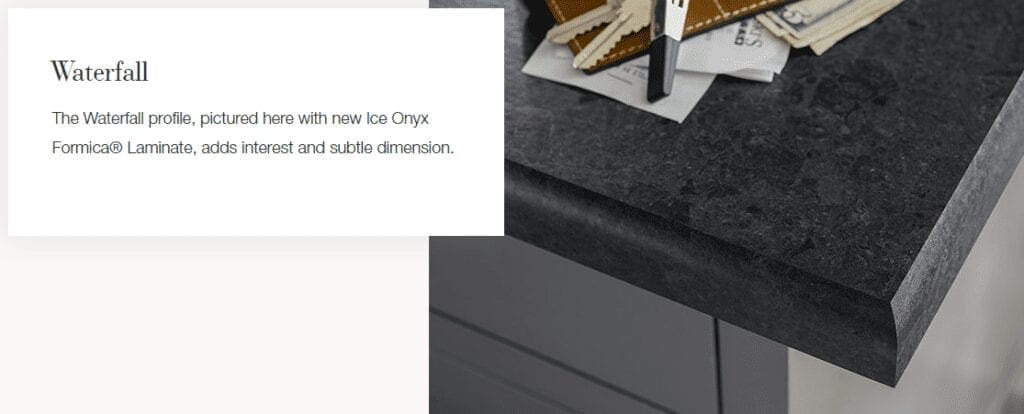

Ultra-Top Waterfall

The smooth 1-1/2” thick front nose along with the 3/4” radius makes this the perfect countertop to complement today’s modern look. The simplicity of this countertop will enhance the look of any room.

Countertop Edges

Explore The Possibilities of Commercial Grade Laminates at S&W Cabinets

The possibilities are endless with todays commercial Grade laminates

- Full array of solids, patterns & textures

- Durable

- Functional

- Versatile

- Highly heat resistant

- Nearly impossible to stain

- Are more impact resistant than stone

- Are easier to maintain than stone

Formica® Standard Designs

CLICK ON A SAMPLE BELOW TO VIEW A LARGER IMAGE

Wilsonart® Standard Designs

CLICK ON A SAMPLE BELOW TO VIEW A LARGER IMAGE

How To Keep Your Laminate Countertops Clean

To clean plastic laminate countertops on a daily basis, you only need to use dishwashing liquid, warm water and a microfiber cloth. Apply a mixture of dish soap and water to your counters using the cloth. As you wipe the counter, rinse your cloth in clean water.

To make your countertop shine again, use a mild car wax in a light layer. This will bring out the faded color, as well as leave a protective coating to keep the laminate at its best all year long.

CORE SUBSTRATES

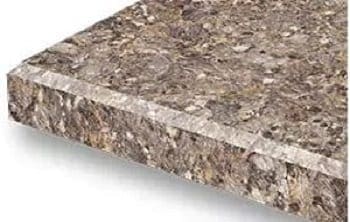

Particleboard

Particleboard is the standard wood core for Hartson-Kennedy laminate countertops.

On any given day, saw mills and other wood processing factories generate a significant amount of manufacturing by-product and scrap material. Much of these wood shavings and piles of sawdust are recycled and end up as an engineered wood product called particleboard. Particleboard is a value-packed alternative to solid wood paneling or boards. It is primarily intended for interior projects in which size consistency, smooth surfaces, and a homogeneous construction are a priority.

Examine a section of particleboard and you’ll most likely notice a lack of grain. Particleboard is produced by combining sawdust and other wood scrap with a special resin. This slurry of wood chips and glue is then pressed through an extrusion machine to form long sheets of particleboard. Customized saws cut these sheets into various sizes according to the needs of the customer. Countertop manufacturers use particleboard in a variety of sizes, but generally ¾” thick panels in 30″ widths in 8’, 10’ and 12’ lengths are most suitable for countertop cores.

Although unfinished particleboard bears little resemblance to traditional hardwoods, its smooth, consistent surface is ideal for lamination. One of the things conventional particleboard cannot handle, however, is high exposure to moisture. This is why few if any outdoor projects feature particleboard.

Direct and/or prolonged contact with water can cause particleboard to stain, warp or swell. Moisture resistant (MR) type particleboard performs much better in higher moisture applications.

Particle Board Spec Sheet PDF’s

http://www.hartson-kennedy.com/wp-content/uploads/2018/07/duraflake_plus.pdf

http://www.hartson-kennedy.com/wp-content/uploads/2018/07/duraflake_standard-PB.pdf

http://www.hartson-kennedy.com/wp-content/uploads/2018/07/Georgia-Pacific-Particleboard-621763.pdf

http://www.hartson-kennedy.com/wp-content/uploads/2018/07/UltraBlend_Dillard_Tech_Data_121615.pdf

Plywood

Plywood is a wood product manufactured out of many sheets of veneer, or plies, pressed together and glued, with their grains going in opposite directions.

Plywood tends to be extremely strong and is treated in many different ways depending upon its intended application.

Because of the way in which plywood is constructed, it also resists cracking, bending, warping, and shrinkage–depending upon its thickness. Plywood is also referred to as an engineered wood, although it is made from a composite of wooden materials, and various forms of it have been made for thousands of years.

The plies that form plywood are generally cut on a rotary lathe, which cuts a continuous roll of wood while a log, called a peeler, is turned against it. Rotary lathing is rapid and makes efficient use of the wood while turning out veneers highly suitable for plywood.

Rotary lathe veneers tend to be dull in appearance, although perfectly functional for use as a countertop core. After the veneers are cut, they are overlaid with layers of glue and pressed together until dry to form a flat, even, tight piece of plywood. Plywood is sturdier than regular sheets or panels of wood because the veneers are laid with their grains opposing, which also causes the wood product to resist warping because the grains pull each other tight.

Plywood comes in a number of forms, including softwood plywood, which is made from pine, fir, or spruce. Softwood plywood is usually pale in color and is used in construction applications. Plywood can also be decorative, with a facing veneer of exotic hardwoods. Mahogany or birch is used to create an extremely strong type of plywood known as aircraft plywood, because it was utilized in the construction of aircraft through the Second World War.

When plywood is destined for use as a countertop core in an indoor application, it is made with urea-formaldehyde glue, which dries quickly and is a good value. For plywood intended for use in outdoor applications or wet environments, a more expensive water resistant glue is used to prevent the plies from coming apart, or delaminating, and compromising the strength of the plywood. Plies range in thickness depending upon the plywood panels they are used in, from 1/10 inch (approximately 1/5 centimeter) to 1/6 inch (almost 1/5 centimeters). Standard plywood sizes consist of four foot by eight foot (1.2 by 2.4 meter) sheets in three, five, or seven plies. Plywood intended for countertop applications is normally manufactured in a ¾” thickness (23/32″), features 7-ply construction, and comes in 30″ by 8’, 10’ and 12’ lengths. Plywood cores for countertop construction are sometimes a specification requirement for HUD installations.

MDF (Medium Density Fiberboard)

Medium density fiberboard, or MDF, is a composite wood product similar to particleboard. It’s made out of wood waste fibers glued together with resin, heat, and pressure. MDF is appropriate for many applications, from cabinetry to molding and is great for countertops because it is smooth uniform, and less prone to warping.

MDF has many advantages over plywood, particleboard, or high-density fiberboard. It’s very smooth because the wood fibers used in its manufacture are uniform and fine. This makes it have low “tear out,” which means that when sawed, the end has a smooth cut instead of a more jagged edge. MDF panels machine very well with carbide tooling and have smooth profiles after the shaping process. MDF also has a mild reaction to moisture, meaning it is less prone to warping or swelling in high-humidity applications like a kitchen or bathroom environment.

Builders and fabricators use MDF in many capacities, such as laminate countertops, furniture, shelving, laminate flooring, decorative molding, and doors. They value MDF for its insular qualities in sound and heat. Also, it can be nailed, glued, screwed, stapled, or attached with dowels, making it a truly versatile core material.

Reconstituted, engineered wood products like MDF are often covered with a laminate or veneer sheet. Some people prefer using MDF over regular plywood or lumber products because it has a lower impact on the environment. MDF is solely made from waste products, the leftover scraps that would otherwise be dumped in a landfill. This attraction has helped it gain popularity among homeowners.

NAUF (No Added Urea Formaldehyde) MR (Moisture-Resistant) Particleboard

NAUF MR Particleboard is made of recycled or recovered wood fiber particleboard engineered to meet today’s green building requirements.

It is produced with an ultra-low emitting formaldehyde resin system. It is also moisture resistant and meets the moisture resistant specification for category MR10 with a 5.5% maximum thickness swell, demonstrating enhanced dimensional stability in high humidity environments. These attributes make it an ideal substrate for countertops.

S&W CABINETS, Inc.

CORPORATE OFFICE

490 Cummins Dr.

Chaffee, Missouri 63740

Contact us on FB Messenger HERE

Corporate Office (573) 887-3100

RESIDENTIAL CUSTOM &

SEMI-CUSTOM DIVISION

3319 State Hwy. M.

Chaffee, Missouri 63740

Contact us HERE

Phone: (573) 887-3471

COMMERCIAL ARCHITECTURAL

CASEWORK DIVISION

490 Cummins Dr.

Chaffee, Missouri 63740

Contact us HERE

Phone: (573) 887-3100